Industrialized hydrothermal cracking technology for fertilizer production

Technical Note:

The heat energy is conducted by special mineral oil, and the pyrolysis reactor is heated and pressurized (180-250 °C, 1.5-2.45MPa), so that livestock and poultry manure, slaughtering waste, animal carcasses, straw, branches, tail vegetables and other organic materials of automatic plant origin are fully hydrothermal cracking reaction in the reactor to form organic fertilizers with small molecular structures. The whole production process lasts 4-6 hours, the product performance is excellent, high nutrients, high organic matter, fully harmless treatment, stable and no burning seedlings. It is the leading international disruptive technology in the industry.

Technical principle:

Through the action of water molecules, components such as cellulose, hemicellulose, starch, lignin, fat and protein in organic matter are decomposed. Organic macromolecules are degraded into products with smaller molecular weight under the action of water molecules. At the same time, a large number of small molecules enter the liquid phase through mass transfer such as diffusion and become organic components and nutrients in the liquid.

Two systems:

Biomass gasification combustion energy supply system and industrial hydrothermal cracking fertilizer production system, both of which adopt Tsinghua's patented technology, and are equipped with intelligent control systems, intelligent operating systems with independent diagnosis, error correction and learning capabilities.

The first part of biomass gasification combustion energy supply system: Tsinghua's patented gasification combustion technology, which can efficiently and environmentally protect a large number of crop straw, waste branches and other planting wastes for energy conversion, and at the same time treat a variety of agricultural and rural solid wastes such as agricultural film fruit bags, provide energy for the preparation of organic fertilizer system (can also provide heat source for industrial and agricultural heat), the system can easily achieve ultra-low emissions, meet environmental protection requirements.

The second part of the industrial hydrothermal cracking fertilizer system: through sufficient hydrothermal cracking, organic wastes such as straw, planting waste, breeding manure, aquatic waste, and animal carcasses are industrially prepared into high-quality solid and liquid organic fertilizer.

1) The system is intelligently controlled, which can prepare solid and liquid organic fertilizer at the same time with ultra-high efficiency, which can realize the daily production of human and livestock manure, and truly reduce, recycle and harmless;

2) No composting, low-carbon environmental protection, relatively small land occupation compared to the needs of the same industry, in line with carbon emission reduction requirements;

3) Fertilizer products present a small molecular structure that is easy for plants to absorb, inactivated by high temperature and high pressure, killing viral bacteria and insect eggs in many aspects, thoroughly decomposing toxic and harmful substances such as antibiotics, hormones, pesticides, veterinary drug residues, etc., stable traits will not burn seedlings, increase yield and improve taste, suitable for high standards of crop application;

4) The products are randomly inspected, the total nutrients and organic matter content are far better than the national standard, and further allocated to make a variety of crop special fertilizers and biological fertilizers.

- Technical Advantages

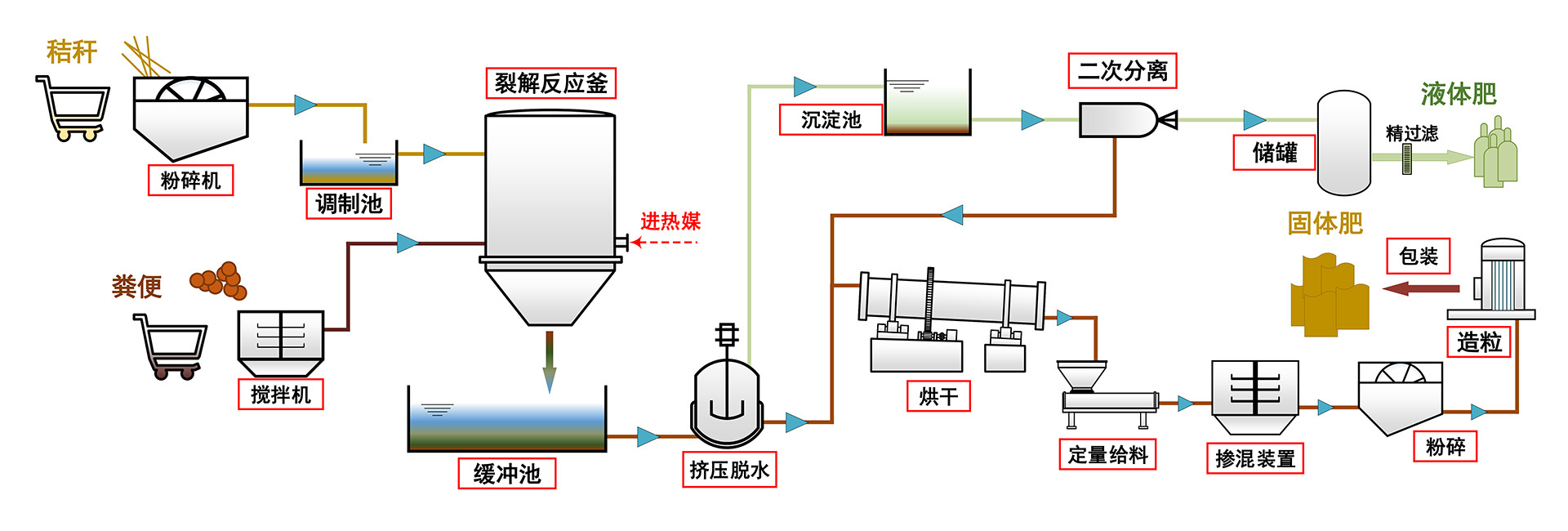

- Technical Process

- Technical Comparison

- Technical Novelty Search

- Awards&Patents

-

- Commodity name: Industrialized hydrothermal cracking technology for fertilizer production

<p><strong>Technical Note:</strong></p> <p>The heat energy is conducted by special mineral oil, and the pyrolysis reactor is heated and pressurized (180-250 °C, 1.5-2.45MPa), so that livestock and poultry manure, slaughtering waste, animal carcasses, straw, branches, tail vegetables and other organic materials of automatic plant origin are fully hydrothermal cracking reaction in the reactor to form organic fertilizers with small molecular structures. The whole production process lasts 4-6 hours, the product performance is excellent, high nutrients, high organic matter, fully harmless treatment, stable and no burning seedlings. It is the leading international disruptive technology in the industry.</p> <p><strong>Technical principle:</strong></p> <p>Through the action of water molecules, components such as cellulose, hemicellulose, starch, lignin, fat and protein in organic matter are decomposed. Organic macromolecules are degraded into products with smaller molecular weight under the action of water molecules. At the same time, a large number of small molecules enter the liquid phase through mass transfer such as diffusion and become organic components and nutrients in the liquid.</p> <p><strong>Two systems:</strong></p> <p>Biomass gasification combustion energy supply system and industrial hydrothermal cracking fertilizer production system, both of which adopt Tsinghua's patented technology, and are equipped with intelligent control systems, intelligent operating systems with independent diagnosis, error correction and learning capabilities.</p> <p><strong>The first part of biomass</strong> gasification combustion energy supply system: Tsinghua's patented gasification combustion technology, which can efficiently and environmentally protect a large number of crop straw, waste branches and other planting wastes for energy conversion, and at the same time treat a variety of agricultural and rural solid wastes such as agricultural film fruit bags, provide energy for the preparation of organic fertilizer system (can also provide heat source for industrial and agricultural heat), the system can easily achieve ultra-low emissions, meet environmental protection requirements.</p> <p><strong>The second part of the industrial</strong> hydrothermal cracking fertilizer system: through sufficient hydrothermal cracking, organic wastes such as straw, planting waste, breeding manure, aquatic waste, and animal carcasses are industrially prepared into high-quality solid and liquid organic fertilizer.</p> <p>1) The system is intelligently controlled, which can prepare solid and liquid organic fertilizer at the same time with ultra-high efficiency, which can realize the daily production of human and livestock manure, and truly reduce, recycle and harmless;</p> <p>2) No composting, low-carbon environmental protection, relatively small land occupation compared to the needs of the same industry, in line with carbon emission reduction requirements;</p> <p>3) Fertilizer products present a small molecular structure that is easy for plants to absorb, inactivated by high temperature and high pressure, killing viral bacteria and insect eggs in many aspects, thoroughly decomposing toxic and harmful substances such as antibiotics, hormones, pesticides, veterinary drug residues, etc., stable traits will not burn seedlings, increase yield and improve taste, suitable for high standards of crop application;</p> <p>4) The products are randomly inspected, the total nutrients and organic matter content are far better than the national standard, and further allocated to make a variety of crop special fertilizers and biological fertilizers.</p>

1) Ultra-high rate conversion, which can realize the daily production of human and livestock manure, truly reduced, recycling, and harmless;

2) High temperature and autoclave inactivation, multi-faceted killing of viral bacteria and insect eggs;

3) Thoroughly decompose toxic and harmful substances such as antibiotics, hormones, pesticides, veterinary drug residues, etc.;

4) At the same time, produce solid fertilizer and liquid fertilizer with high nutrient and high organic matter content, and the product characteristics are stable, eliminating burning seedlings;

5) Convert large molecules such as lignin, cellulose, pectin, starch, protein and other macromolecules in organic matter into small molecular structures, increase the content of absorbable organic matter, and greatly improve fertilizer efficiency;

6) No need for composting and fermentation, no environmental pollution such as waste gas and wastewater, safe and environmentally friendly, small land occupation;

7) Industrial production, not affected by climate environment, stable and reliable product quality;

8) Equipment and facilities are modular, serialized, intelligent, fool-style and easy to operate, small workload of workers, low labor intensity;

9) On-site recycling of agricultural waste, replenishing the fertility of soil loss, effectively maintaining the organic balance of the ecological environment, and ensuring food safety at the source.

-

Industrial water thermal cracking method to prepare organic fertilizer technology

The original hydrothermal cracking method to prepare organic fertilizer production process is mainly to transport the tempered vegetable straw, vegetable and fruit waste, breeding manure, agricultural toilet manure and other planting and breeding wastes as organic materials to the hydrothermal cracking reactor respectively. Through the energy system energy supply, the material is hydrothermal cracking reaction and stabilized under the conditions of 180-250 °C and 1.5-2.45MPa (depending on the raw material situation). The whole process of fertilizing takes no more than 4 hours.

The process comprehensively kills bacteria, viruses and insect eggs, decomposes toxic and harmful substances such as antibiotic hormones, and can passivate some heavy metals, make the fertilizer structure small molecule, increase the content of absorbable organic matter, and promote the absorption and absorption of crops. After hydrothermal cracking, the organic materials are separated from solid and liquid, and safe and efficient organic solid fertilizer and liquid fertilizer are prepared respectively. The new process subverts the traditional fermentation and fertilization method, greatly improves production efficiency and product quality, and realizes mechanization, automation, standardization and intelligent production of fertilizer making process.

-

Project

Existing conventional fertilizer making process

Fertilization process of this program

Security

The fertilizer temperature is low, below 70 °C, and insect eggs, germs, etc. cannot be effectively killed; Incomplete breakdown of antibiotics and hormones.

Kills all viruses, germs and eggs; Complete decomposition of toxic substances such as antibiotics and hormones.

Eco-friendliness

Compost gas produces a significant greenhouse effect

No compost gas is generated, significantly reducing carbon emissions

Fertilizer efficiency

Composting at room temperature, fermentation takes 15-40 days, fertilization efficiency is low

High temperature curing, only 3-4 hours, high production efficiency

Fertilizer effectiveness

Different materials have different rotting conditions, it is difficult to mix and dispose of a variety of materials, and the rotting conditions are affected by climate and site, the operating conditions are unstable, and the product quality is uneven, which will cause crop growth obstacles

A variety of animal sources react simultaneously with plant sources, rapid decomposition and high stability, standardized production process makes fertilizer quality reliable, does not burn seedlings, fertilizer structure small molecular crops are easy to absorb; Fertilizer local crops to supplement nutrients in the soil; Trace elements and beneficial bacteria can be supplemented according to the needs of different crops

Occupancy

big

small

Artificial

The workload is large and the labor intensity is high

Mechanized automated production, small workload, low labor intensity

Project

Aerobic fermentation

Anaerobic fermentation

Vermicompost

Hydrothermal cracking to fertilizer

Principle

Under aerobic conditions, aerobic bacteria absorb, oxidize and decompose materials.

The material is stabilized under anaerobic conditions by the metabolic activity of microorganisms, accompanied by the production of methane and CO2.

Earthworms use their activities to break down organic waste into easy-to-use nutrients.

Organic fertilizer is produced by hydrolysis of raw materials at 180-250 °C and 1.5-2.45MPa (depending on the raw material) for 1-2.5 hours.

Material adaptability

So so

difference

difference

strong

Excipients added

big

big

big

small

Product yield

40~50%

30~40%

30~40%

>90%

Processing cycle

20~30d

40~60d

60~90d

3~4h

Product Variety

solid

solid

solid

Solid, Liquid

Product perception

Slightly odorous

stench

Slightly odorous

No odor

Nutrient indicators

NPK≥ 4% organic matter≥ 30%

NPK≥ 4% organic matter≥ 30%

NPK≥ 4% organic matter≥ 30%

NPK≥ 6% organic matter≥ 40%

Application effect

So so

difference

So so

Good

Health indicators

So so

difference

So so

Good

Floor space

big

big

big

small

Secondary pollution

big

So so

big

small

Influenced by climate

So so

big

big

small

System stability

So so

low

low

high

Investment costs

So so

high

high

low

Operating costs

So so

high

high

low

Degree of automation

So so

So so

low

high

Operating environment

difference

So so

difference

Good

Job security

So so

low

So so

high

Environmental benefits

difference

So so

So so

Good

Economic benefits

difference

So so

So so

Good

Social benefits

difference

So so

So so

Good

Comparison of carbon and nitrogen loss during aerobic composting of organic solid waste and industrial hydrothermal cracking

The traditional aerobic composting process is to put manure in the open air after 15-45 days of aerobic fermentation, nutrient and organic matter loss is large, resulting in a large amount of carbon emissions, is an important source of agricultural carbon emissions.

The hydrothermal cracking fertilizer process is to carry out hydrothermal cracking reaction of manure, vegetable straw and other materials in a closed facility, with very small carbon and nitrogen loss, and fully retained in the product as effective nutrients and organic matter.

Type of technology

Carbon Loss (%)

CO2-C/TC(%)

Nitrogen loss (%)

NH3-N/TN(%)

TC

CO2-C

TN

NH3-N

Aerobic composting

35~68

31~58

>70

22~45

12~42

>60

Hydrothermal cracking

2~11

2~5

>90

-

-

-

- TC: Total carbon

- TN: Total nitrogen

- CO2-C: Carbon lost in the form of carbon dioxide

- NH3-N: Carbon and nitrogen lost as ammonia

The above data comes from public literature at home and abroad

-

-

Science and technology evaluation: international leading level

The Ministry of Industry and Information Technology's first "Light of Innovation" outstanding achievements in technological innovation of small and medium-sized enterprises

People's Daily Network 2022 Healthy China Action Innovation Practice Excellent Case

2022 China's agricultural green and low-carbon innovation benchmarking enterprises TOP10

The third prize of the 2022 Maker Competition, the TOP150 Award of the Enterprise Group, and the Winner of the Special Competition have three golden unicorn trophies