Agricultural product drying system

This technology is suitable for the rapid drying of root-like agricultural products such as cassava, sweet potatoes, and potatoes, and is introduced using the difficult Thai cassava processing as an example.

With the gradual maturity of deep processing technology, cassava has gradually become a world-recognized cash crop with high comprehensive utilization value and important industrial raw materials, but cassava has high water content, if not dried, it is easy to mold and deteriorate, and it is not good to store. Cassava drying means are generally natural drying and the use of drying equipment two ways, the use of natural drying is affected by the weather, the use of general drying equipment has high energy consumption and low efficiency. At present, the drying technology level of most enterprises is not high, the drying process is simple and extensive, the quality of raw materials is mixed, the technical content is low, the product quality is unstable, and the energy consumption is high.

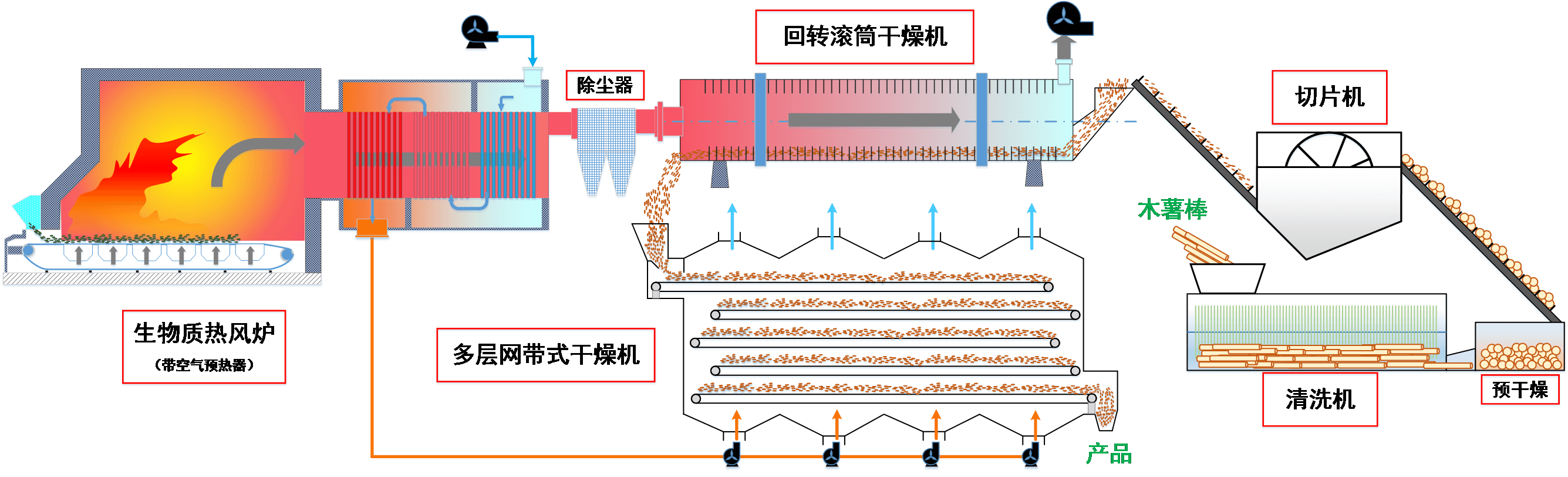

For the characteristics of cassava, Beijing Heshi Technology Co., Ltd. and Tsinghua University jointly developed (drum + mesh belt two-stage) cassava drying process, the production line consists of drum washer, pre-dryer, slicer, drum power machine and belt dryer five parts, fresh cassava in turn through the above five links, pre-dryer to remove water on the surface of cassava, drum power machine can remove 70% of moisture, belt dryer and then through three layers of rolling belt layer by layer drying. The moisture content of the finished product produced by the production line is less than 12%, and the ton treatment cost is less than 175 yuan, which has the outstanding advantages of high efficiency and low cost, which can bring good economic benefits to growers and processing enterprises.

- Technical Advantages

- Technical Process

- Technical Comparison

- Technical Novelty Search

- Awards&Patents

-

- Commodity name: Agricultural product drying system

<p><strong>This technology is suitable for the rapid drying of root-like agricultural products such as cassava, sweet potatoes, and potatoes, and is introduced using the difficult Thai cassava processing as an example.</strong></p> <p>With the gradual maturity of deep processing technology, cassava has gradually become a world-recognized cash crop with high comprehensive utilization value and important industrial raw materials, but cassava has high water content, if not dried, it is easy to mold and deteriorate, and it is not good to store. Cassava drying means are generally natural drying and the use of drying equipment two ways, the use of natural drying is affected by the weather, the use of general drying equipment has high energy consumption and low efficiency. At present, the drying technology level of most enterprises is not high, the drying process is simple and extensive, the quality of raw materials is mixed, the technical content is low, the product quality is unstable, and the energy consumption is high.</p> <p>For the characteristics of cassava, Beijing Heshi Technology Co., Ltd. and Tsinghua University jointly developed (drum + mesh belt two-stage) cassava drying process, the production line consists of drum washer, pre-dryer, slicer, drum power machine and belt dryer five parts, fresh cassava in turn through the above five links, pre-dryer to remove water on the surface of cassava, drum power machine can remove 70% of moisture, belt dryer and then through three layers of rolling belt layer by layer drying. The moisture content of the finished product produced by the production line is less than 12%, and the ton treatment cost is less than 175 yuan, which has the outstanding advantages of high efficiency and low cost, which can bring good economic benefits to growers and processing enterprises.</p>

1) High drying strength. The circular drying process is adopted, and the plate reading is set in the drum to ensure that the heat energy and the material are fully in contact with the material in the dynamic process, and the water vapor is discharged quickly, which greatly increases the output of the dryer of the same volume.

2) Low drying cost. The heating equipment (hot blast furnace) uses biomass as fuel, and the flue gas can be used directly, which greatly reduces the drying cost.

3) High energy saving. Using the "drum-mesh belt" two-stage drying scheme, especially corresponding to the cassava constant speed and reduced speed drying stage, compared with the traditional technology, the drying time is shortened by 50% and the heat utilization rate is increased by 99.9%.

4) Continuous operation, large production capacity. The tilting drum is combined with multi-layer mesh belts to achieve continuous production in the whole process, with a product volume of up to 4 t/h and a daily processing capacity of more than <> tons.

5) High degree of mechanization and high operating flexibility. The cleaning, slicing and drying equipment adopts automatic control and has multiple temperature measurement points, and the operating parameters such as inclination, speed, and mesh belt transmission speed are adjustable, and the output of the product is allowed to fluctuate greatly.

6) Good product quality uniformity. The thickness of the product is uniform (6~8mm), less damage, uniform drying, and the moisture content deviation of the product is ±1%.

-

-

To be entered...

-

To be entered...

-

To be entered...